What Would Cause a Blower Motor to Stop Operating and Then Start Again

Electric Motor Overheat Diagnosis

Electric Motor Overheat Diagnosis

Overheating electric motor may trip thermal reset button

- POST a QUESTION or Annotate almost how to troubleshoot electric motors such as air conditioning compressor motors, heating equipment burner or fan motors, swimming pool motors, h2o well pump motors

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Overheating electrical motor diagnosis and repair:

This commodity provides a tabular array of the causes of and cures for an electric motor that overheats or runs as well hot. If your electric motor keeps tripping the thermal reset push this table helps find the cause and cure.

This serial commodity describes A/C electrical motor troubleshooting: hither we provide an electrical motor diagnostic table, a troubleshooting guide that helps diagnose and repair virtually electric motor issues for motors found on HVAC equipment in buildings such every bit air conditioners, furnace or air handler blower fans, oil burner motors, well pumps, and condensate render pumps.

We also provide an Commodity INDEX for this topic, or you can try the page elevation or bottom SEARCH BOX equally a quick way to find information you lot demand.

Overheating Electric Motor Troubleshooting

Provided here: a Table of Air Workout or Heating Organization Electric Motor Troubleshooting Procedures for a Motor that Overheats or Trips its Reset Button or Runs at Abnormal Electric current or Voltage.

Fatal Shock Run a risk Warning : Inspecting electrical components and systems risks death past electrocution as well as serious burns or other injuries to the inspector or to others. Practice non attempt these tasks unless yous are properly trained and equipped.

See DMMs VOMs Safe USE OF for assist in making safe use of electrical test equipment before yous kickoff poking your meter probes into anything.

At page top our photo illustrates the motor equally typically found in a direct-bulldoze HVAC blower or air handler assembly.

Picket out: Never simply supersede a burned-out electric motor without also finding and fixing the cause of the fire-out. Otherwise y'all'll just be replacing the motor over again. And over again.

Table B: 7 Things to Bank check if an Electric Motor Starts merely Overheats and Trips its Reset Push or Runs at Aberrant Voltage or Current Levels | ||

| Come across Electric MOTOR OVERLOAD RESET SWITCH find and reset this push button If your electrical motor won't start or won't run, see ELECTRIC MOTOR WON'T START / RUN. | ||

| one: Bad line VOLTAGE | Utilise a VOM to check the voltage level at the pressure command switch See: AMPS MEASUREMENT METHODS DMM DIGITAL MULTIMETER HOW TO Use DMMs & VOMs, Using Safely VOLTS / AMPS MEASUREMENT EQUIP SAFETY for Electric INSPECTORS Examination EQUIPMENT, ELECTRICAL GUIDE | If voltage is too low, check voltage at the electrical console and check that the proper size wiring was used for the ampacity and length of run and that there are no partial shorts or damaged wires or connectors |

| 2: Incorrect electrical motor WIRING | Cheque the actual electrical wiring against the motor wiring diagram or the installation manual for the equipment | Reconnect wiring properly |

| 3: Electric MOTOR runs too HOT due to surroundings - inadequate ventilation, operating weather Or The electric motor is overloaded. | Cheque the air temperature where the motor is located. If the air temperature is over 100 degF, the pump may be also hot and its thermal overload switch tripping because of the environment, not a pump problem. Operating conditions tin cause a motor to overheat, such as a well pump that runs continually considering of other problems in the water organisation An air conditioner compressor motor that is overheating may sometimes be re-started by cooling the equipment with water (watch out for shorting electrical components). This is a diagnostic footstep not an adequate repair measure out. Whatever electric motor that is being asked to operate equipment whose forced exceed the motor's rated capacity will run hot and will ultimately burn-up, or fail to start. If the motor starts and runs normally when disconnected from its load just has problem starting when re-installed, the problem could exist on the load end . A common instance is trouble at an electric motor on a heating oil burner whose fuel unit (oil pump) drive shaft is binding. Causes of electric motor overloading include and too-hot operation include Low supply voltage Damage or binding in the driven-mechanical system that the motor is operating College ambient temperature than the motor is rated to handle Worn bearings Excessive duty bike Internal damage in the motor: shorted or grounded winding (may show up only afterward the motor has spun upward to full operating speed) | Install adequate ventilation, or if needed, shading, or relocate the motor/equipment to a absurd location Look for abnormal weather condition that cause the motor to keep running (bad control, loss of well water, bad pump controls, water left running in the edifice, valve airtight on pump outlet side, strainer chock-full at pump inlet or outlet, pump running continually due to improper voltage, pump running backwards due to electric damage or mis-wiring or starter capacitor short) A well pump motor may run continually and be unable to achieve shut-off pressure due to a damaged impeller or loss of well water. See ELECTRIC MOTOR RUN DIRECTION Run into ELECTRIC MOTOR OVERLOAD RESET SWITCH |

| 4: Electric MOTOR runs too long or WON'T Shut OFF | Check for a bad switch or motor control assembly. Example: If the well recovery rate is too poor and the pump is operating at low water force per unit area, possibly considering a tailpiece is installed to preclude air injection and pump burnup, the pump may exist overheating. As well see step 6 in this table. | Air conditioner & heat pump motors: check refrigerant level. An air conditioner or heat pump compressor motor may overheat or even be destroyed past having run with very long on-cycles due to a refrigerant leak and a lost refrigerant charge. Water pump motors: Install a valve on the water belch line and reduce water flow to increase water pressure within the pump itself. See Water Force per unit area Trouble DIAGNOSIS Tabular array Run into Air Conditioner Long on cycle - Insufficient Cooling - Loose or Worn Compressors |

| v. Excessive or Abnormally HIGH current draw at electrical motor | Running motor amps measurements (current draw): Cheque the motor name plate data and notation the motor's RLA amps rating. Or if available, obtain from the manufacturer detailed specifications for the motor's operation and during start-upwards. LRA tests: (Lock Rotor Amps) Using an ammeter, mensurate the electric current depict of the motor during showtime-upward. Abnormally loftier current draw at the start of a motor on-cycle can indicate mechanical harm to the motor, a developing short in windings (? citation needed), or a bad start-run capacitor. Typical motor start-up current draw in amps will be v-6 times the RLA but very quickly (seconds) the motor electric current describe should fall back to RLA. RLA Tests: (Running Load Amps) Using an ammeter, measure the actual electric current draw of the motor during performance. While the specific tolerances will vary depending on motor, motor design, and application, if the current draw measured in Amps is significantly college than the manufacturer's specifications (typically RLA or the amperage expected when the motor is running under load) the motor may be failing or its driven parts may be failing . Don't get fooled: Bad crankcase heater: Attempting to start a declining or failed air conditioner/oestrus pump compressor motor can describe very loftier current. Simply a failed crankcase heater on a heat pump compressor motor trying to start in cold atmospheric condition may deliver similar symptoms. A faulty overload safety relay control on a motor (not present on all motors) can shut down a motor that is working usually, fooling you into thinking that the motor is drawing excessive current. See: AMPS MEASUREMENT METHODS DMM DIGITAL MULTIMETER HOW TO Utilise DMMs & VOMs, Using Safely VOLTS / AMPS MEASUREMENT EQUIP Rubber for Electric INSPECTORS Test EQUIPMENT, ELECTRICAL GUIDE | Excessive LRA: if present, try replacing the commencement-run capacitor. Come across CAPACITORS for HARD STARTING MOTORS. For air conditioners & oestrus pumps see BURNED-OUT COMPRESSOR For rut pumps, also see CRANKCASE HEATERS Excessive RLA: Farther investigation may exist needed past directly examination of the motor and the mechanical components that information technology is driving. Examples: |

| six. Abnormally Depression current or Amps depict at an electric motor | Low amperage draw may indicate internal motor wear or more likely, worn parts mechanically driven by the electric motor Example i: in testing an air conditioner or heat pump compressor motor, unlike a high-amp current draw which indicates that the compressor is danged internally in a way that its piston(southward) is (are) tight in the cylinder, a depression-amp current draw, if below normal, may ostend internal habiliment on the compressor parts, and would support the diagnosis that the compressor is worn and inefficient. Instance 2: a well pump or heating circulator pump or oil burner motor whose coupling to the mechanically-driven components has cleaved completely may draw low current Example 3: a well pump or water pump that is running "dry" (no water in the well) will draw abnormally depression current. Run across: AMPS MEASUREMENT METHODS DMM DIGITAL MULTIMETER HOW TO USE DMMs & VOMs, Using Safely VOLTS / AMPS MEASUREMENT EQUIP Rubber for Electric INSPECTORS Test EQUIPMENT, ELECTRICAL GUIDE | Where in that location are no gauge ports to actually measure compressor low side and loftier side vacuum and refrigerant pressures, this simple electric test is a useful first pace. Encounter Air Conditioner LONG ON-Bike - Bereft Cooling - Loose or Worn Compressors |

| 7. Bad or jammed internal TEFC electric motor cooling FAN | TEFC electric motors use a totally-enclosed fan for cooling. The fan blades are behind metal guard on the dorsum of the motor. The fan itself should exist deeply fastened to the shaft, should not wobble nor be bent or damaged, and the cooling air inlet openings should not be clogged. - WikiHow [36] Notation: yous won't find this design on residential air conditioners, estrus pumps, well pumps, nor most other home appliances. TEFC motors accept external cooling fins that are quite distinctive. | If the motor has not already failed, clean the motor fan and fan air inlet openings if chock-full and observe whether or not this solves a motor overheating problem. If the motor has not already failed, replace the fan assembly if it is bent, damaged, jammed, will not spin freely - or replace the unabridged motor assembly. |

| eight. NOISY electric motor | Various possible defects could cause an electric motor to jam or demark, such as loose mounts, bad bearings, loose couplings, defects in the driven-assembly or function. If pressing the reset button starts the motor just it runs hot or noisy come across the motor dissonance diagnostic commodity at correct. Check for loftier current depict in a bounden motor. | AMPS MEASUREMENT METHODS RESET Button, ELECTRIC MOTOR Electric MOTOR NOISE DIAGNOSIS |

Notes to the tabular array above

Adapted from various sources including Betta-Flo Jet Pump the National Pump Co. and Adapted & expanded from Beckett (1989) [1]

- BETTA-FLO JET PUMP INSTALLATION Manual,[PDF] National Pump Company, 7706 North 71st Ave., Glendale, AZ 85303, Tel: (800) 966-5240 Email: info@natlpump.com, website: http://www.nationalpumpcompany.com, retrieved anew 9/13/12, original source: http://world wide web.nationalpumpcompany.com/pdf/Betta_Flo_IOM_Jet_Pump.pdf

See also

- Electrical MOTOR OVERLOAD RESET SWITCH

Reader Comments & Q&A

On 2021-02-ten by (mod) - Fluke's list of almost-common causes of electric motor failures

I actually wish I could assist but with then piddling information I don't recall that even past speculation would exist useful. I presume that y'all checked obvious such as improper voltage being delivered.

But courtesy of Fluke, we accept a listing of the nigh-common causes of electrical motor failures:

Power Quality Causes of Electric Motor Failure

- Transient voltage - from the electrical supply, possibly weather condition or load- related.

- Voltage imbalance - in iii-phase systems

- Harmonic Distortion - un-wanted high frequency AC voltages or currents to the windings

Variable Frequency Drive Motor Failure Causes

- Reflections on drive output PWM signals [Pulse Width Modulation]

Excerpt: Variable frequency drives employ a pulse width modulation (PWM) technique to control the output voltage and frequency to a motor. Reflections are generated when there is an impedance mismatch between the source and load. Impedance mismatches can occur every bit a result of improper installation, improper component selection or equipment deposition over time.

- Sigman current - stray currents resulting from signal frequency, voltage level, capacitance and inductance in conductors may cause nuisance tripping or overheated windings.

- Operational overloads - check for abnormal current draw. Fluke says that 30% of motor failrues are caused by overloading!

Mechanical Causes of Electirc Motor Failures

- Misalignment - may exist anguar or parallel or compound misalignment

- Shaft imbalance - oftentimes caused by

Clay accumulation

Missing balance weights

Manufacturing variations

Uneven mass in motor windings and other article of clothing-related factors. - Shaft looseness - may exist acquired by misalignment between the motor'south drive shaft and the driven load

- Begetting article of clothing, oftentimes caused by failure to lubricate the motor properly or by

A heavier load than designed for

Inadequate or incorrect lubrication

Ineffective bearing sealing

Shaft misalignment

Incorrect fit

Normal wear

Induced shaft voltages

Improper Installation Causes of Electric Motor Failure

- Soft foot - rubber or other motor mountain components are worn or missing

- Pipe Srain - extract:

misalignment or long shaft wobble between a drive motor and the driven equipment. Nosotros have seen this with heating circulator pump motors and have gone to sites where at that place was literaly a pile of "dead" electric motors repeatedly replace on the zone circulator considering the installer never noticed that the motor and circulator pump itself were mis-aligned!

- Shaft voltage - extract:

When motor shaft voltages exceed the insulating capability of the begetting grease, flashover currents to the outer begetting will occur, thereby causing pitting and grooving to the begetting races.

Related Electric Motor Get-go Failures

- Bad start or run capacitor (this is not necessarily a motor failure; often a failing motor bearing causes hard-start motors)

- Courtesy of Fluke Corporation, retrived 2021/02/12 original source: https://www.fluke.com/en-gb/larn/blog/motors-drives-pumps-compressors/13-common-causes-of-motor-failure

Contact Fluke at https://www.fluke.com/en-gb/support/technical-support

Fluke's full article includes additional detailed explanation of each of the electric motor failures listed above.

we are facing broken fan issue in our SQ consecration motors, we couldn't find out the root causes of these failures...

we are facing broken fan issue in our SQ consecration motors, nosotros couldn't discover out the root causes of these failures...

Ken

I would commencement by checking the wiring and the ability supply to be sure that the motor is beingness provided with correct voltage. If there's not a power or voltage is too I'm concerned that in that location may be a bad begetting. Information technology says no bad bearing, is information technology possible that the motor was overloaded in apply. Overloading causes about 30% of small-scale electric motor faillures.

If none of those suggest to you that we're on the track of problem information technology might make sense to accept the device or the motor itself to a local motor testing testify where the motor will be run and measurements made of its current describe or amps and other features.

Higher on this page we provide an abbreviated version of Fluke's listing of causes of motor failiures - be sure to accept a loooik.

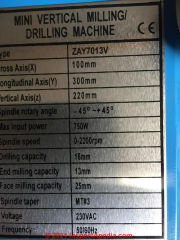

I only brought a minor variable speed Mini Mill for small Engineering Jobs

is was new , ran it for a few hrs , then noticed information technology started to make a few noises in the Motor, which and then lead to motor running hot , I let it cool downwardly for a few hrs tin can dorsum and ran it , for nigh 10 minutes , it clicked out my overload button , I tried to rotate the motor , but it seems it is now seized.

I brought from Interstate , very happy with use of the Machine just sure what I may accept don't or not done.

the seller cannot aid me from his end , willing to pay for repairs , whatever suggestions would be appreciated.

friedman (modernistic)

Anon

Allow'southward kickoff checking out your overheating electric motor by looking through the common causes listed on the page higher up. Let me know what you think.

Hey guys, fifty have a dc motor but it'southward heats

friedman (mod)

I'd bank check the supply voltage, the electrical connections, the controller, and lastly a bad winding.

Yellow phase terminals of my motor always get heated. .the motor is run by frequency drive. .

friedman (mod)

Is it a beginning problem?

Some fans want to be started at hi speed so cutting back.

Why did you lot try a smaller capacitor?

I have bought a Gfc Pedestal fan recently. It becomes overheated at 3 gear (at tiresome speed), I accept replaced the Capacitor to 2.5 uf from 4.5uf. Delight, help me solve the problem of overheating at the lowest speed. Thank you.

...

Continue reading at Electric MOTOR OVERLOAD RESET or select a topic from the closely-related articles below, or run across the complete ARTICLE Alphabetize.

Or run across these

Recommended Manufactures

- Electrical MOTOR DIAGNOSTIC GUIDE - domicile

- A/C Electric MOTOR COMPONENTS

- BURNED-OUT COMPRESSOR

- CAPACITOR TYPES, for MOTORS

- CAPACITORS for HARD STARTING MOTORS

- CHATTERING RELAY Control SWITCHES

- COPELAND Electrical HANDBOOK [PDF]

- ELECTRIC MOTOR 3-Phase

- Electrical MOTOR CENTRIFUGAL SWITCH or PTC PRD

- ELECTRIC MOTOR DATA TAG

- Electrical MOTOR HORSEPOWER & Excursion WIRE SIZE

- Electrical MOTOR LUBRICATION

- ELECTRIC MOTOR Noise DIAGNOSIS

- Electric MOTOR OFF on RESET

- ELECTRIC MOTOR OVERHEATS

- Electric MOTOR OVERLOAD RESET SWITCH

- Electric MOTOR RUN DIRECTION

- Electric MOTOR Starting time SWITCH

- Electrical MOTOR WON'T START / RUN

- Electrical MOTOR TESTS

- ELECTRIC MOTOR WIRING DIAGRAMS & GUIDES

- Hard STARTING COMPRESSOR MOTORS

- Hard STARTING ELECTRIC MOTOR CAUSES

- OIL BURNER NOISE DIAGNOSTIC Index

- RESET BUTTON, ELECTRIC MOTOR

- TIGHT or SEIZED Ac COMPRESSORS

- Water PUMP PROTECTION SWITCH

Suggested citation for this web folio

ELECTRIC MOTOR OVERHEATS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & trouble prevention advice.

Or see this

Index to RELATED ARTICLES: Commodity INDEX to Electrical INSPECTION & TESTING

Or use the SEARCH BOX found below to Enquire a Question or Search InspectApedia

...

Ask a Question or Search InspectApedia

Try the search box simply below, or if you adopt, postal service a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Annotation: appearance of your Comment below may be delayed: if your comment contains an image, web link, or text that looks to the software as if information technology might be a web link, your posting will appear later information technology has been approved by a moderator. Apologies for the delay.

Technical Reviewers & References

Click to Show or Hide Citations & References

Publisher InspectApedia.com - Daniel Friedman

Source: https://inspectapedia.com/electric/Electric-Motor-Overheating.php

0 Response to "What Would Cause a Blower Motor to Stop Operating and Then Start Again"

Post a Comment